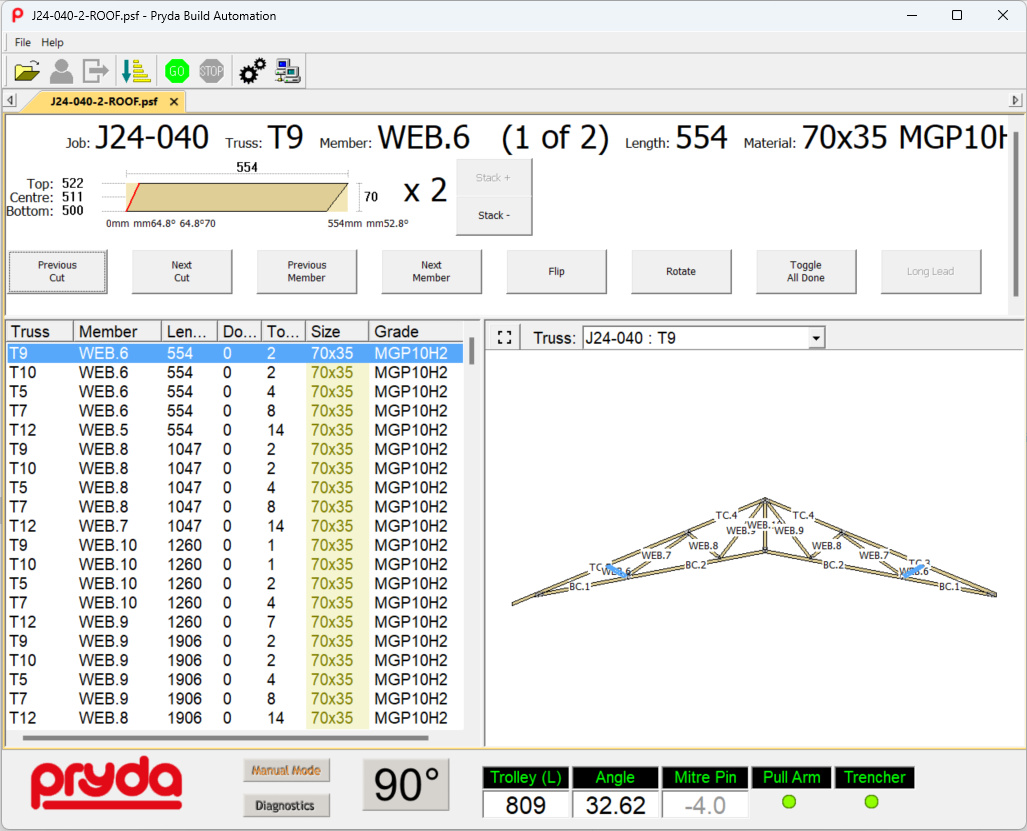

Touchscreen / Industrial PC

Windows Operating System

Direct feedback to Pryda’s Production Manager

Full diagnostics screen

Remote access by Pryda Fabricator Equipment Technicians

Ability to mark truss boot locations on your bottom chord members

Ability to have multiple jobs open at once

PRYDA BUILD AUTOMATION

Pryda Build automation was developed directly with frame and truss businesses to remove aging automation throughout their frame and truss manufacturing facilities.

PBA allows equipment with outdated electrical cabinets along with obsolete Microsoft operating systems to continue to thrive in a competitive market.

CONFIGURATION OPTIONS

| Upgrade an existing system | Pryda supplied new system |

| Existing automated saw, PBA can be replaced on the following existing automation systems, which may already exist within your business – Mango automation – Spida automation – Fruit bat automation – Vector automation | Saw configuration – Angulation saws – Docking saws – Trenching saw / combination saw – Manual plate marking system |

| Existing Plate Progressor system, PBA can be placed on the following existing automation systems – Spida automation – Mango automation | – Plate Progressor system – Nog cutting saw – Sub component cutting system |

| Power | 3 Phase 20 amp |

| Weight | 50kg (Electrical cabinet, pedestal and associated cables) |

DOWNLOAD BROCHURE

RELATED PRODUCTS

- Angulated saws

- Popup saws