Fast and easy to use finish table for wall frame components

Fast reference for squaring of components prior to fastening / nailing

Pneumatic skate ejection system improves manufacturing efficiency

User friendly design permits access from all sides to assist with non-standard wall frame manufacture

Reduced OH&S issues with manual handling

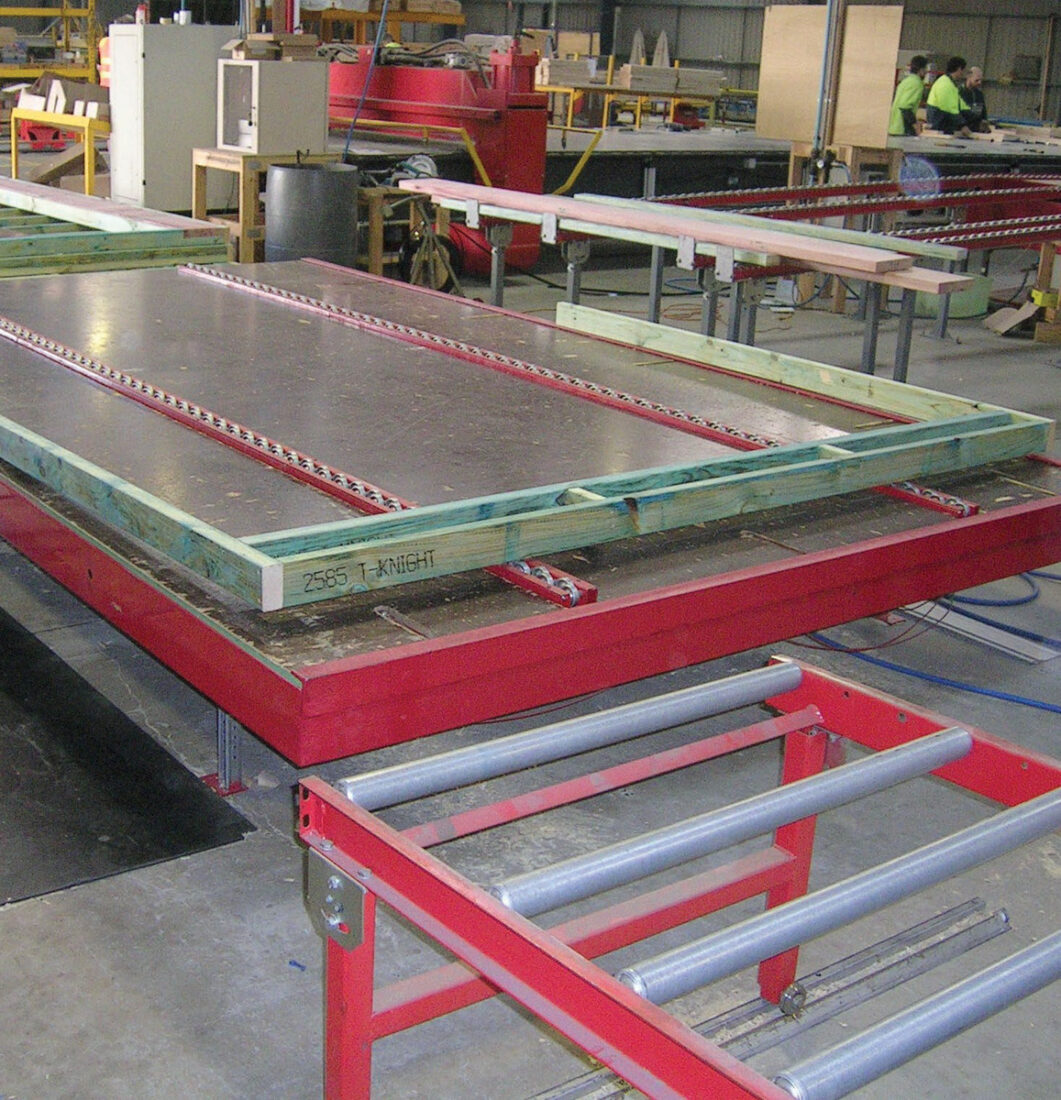

FINISHING TABLE

Pryda’s Finishing Table has been developed as a result of customer feedback on wishing to safely

and easily finish manufacture of frames plus full production of small and non-standard wall frames.

The system’s table top allows flexibility for varying height wall frames.

A shallow height fence provides a square reference guide along two edges of the table ensuring a

quality wall frame finish. Furthermore, the pneumatic side pins provide a squaring and clamping to

the frame without hindering the nailing process.

Inbuilt pneumatically actuated duplex skate rollers assist the lifting and removal of the finished

product to the next stage of the wall frame manufacturing process.

SPECIFICATIONS

| Dimensions | ||

| Overall dimensions (std unit) | – Width (overall) | 2700mm |

| – Length (overall) | 4800mm and 6000mm | |

| – Height (overall) | 450mm (adjustable) | |

| – Weight (approx) | 850kg | |

| Installation requirements | ||

| Power | N/A | |

| Air | Standard 100 psi air supply | |

| Foundation | Sound and level concrete floor |

RELATED PRODUCTS

- Pryda Production Viewer

- Manual outfeed

- Automated outfeed